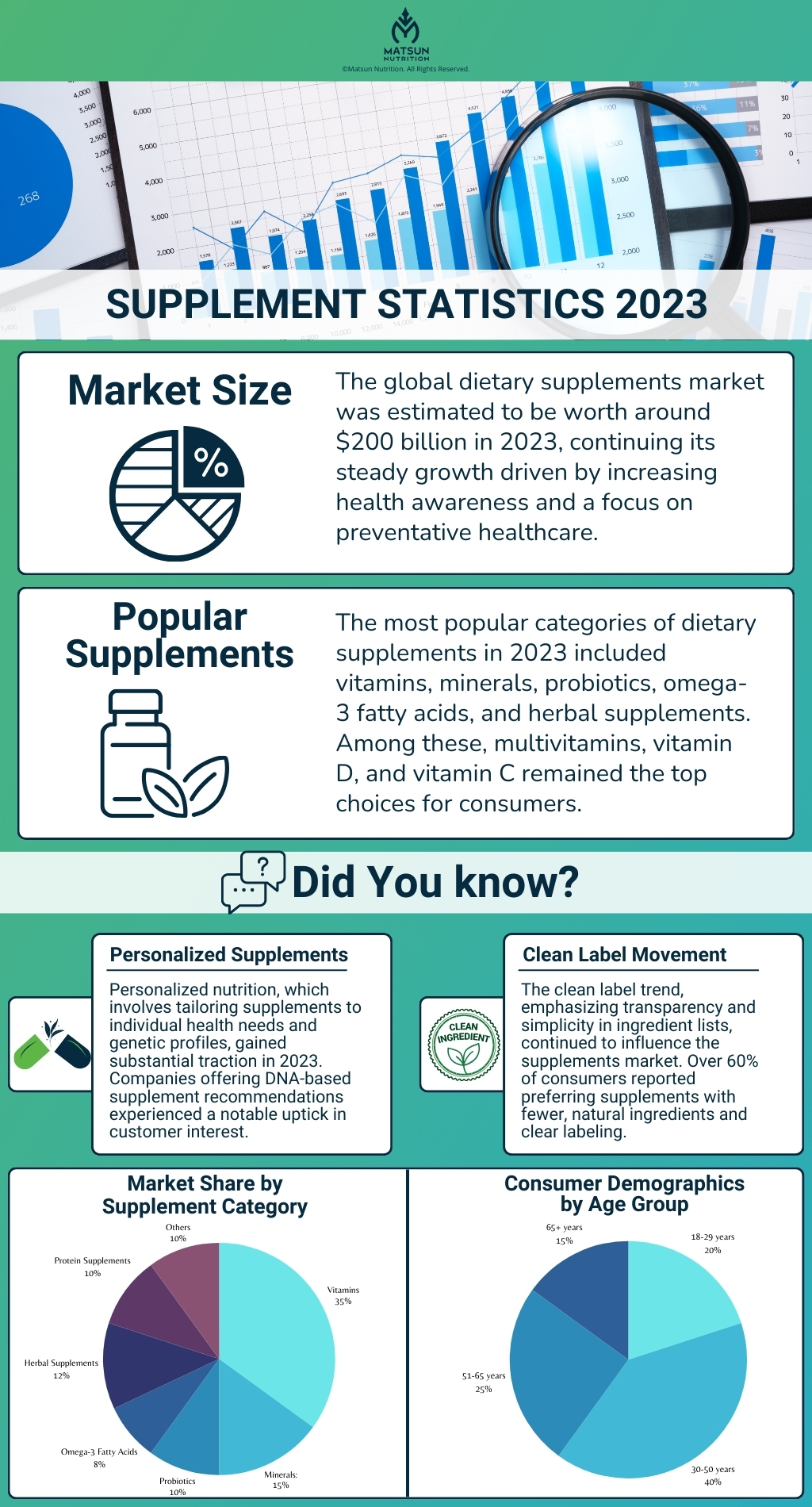

The dietary supplement market is booming, with a global valuation of $358.8 billion in 2023 and a projected growth to $621.8 billion by 2030. For supplement brands aiming to capitalize on this demand, successful supplement manufacturer contract negotiations are a crucial step. Whether you’re a new brand or an established player, understanding how to navigate these contracts ensures clear expectations, quality standards, and mutually beneficial terms.

In this blog, we’ll share seven essential tips to help you master supplement manufacturer contract negotiations, secure a strong foundation for your partnership and position your brand for long-term success.

Key Considerations Before Negotiations

Before plunging into contract negotiations with a supplement manufacturer, there are some preliminary steps you should take. Here are some key considerations that will lay the foundation for a successful agreement:

Choosing the Right Manufacturer

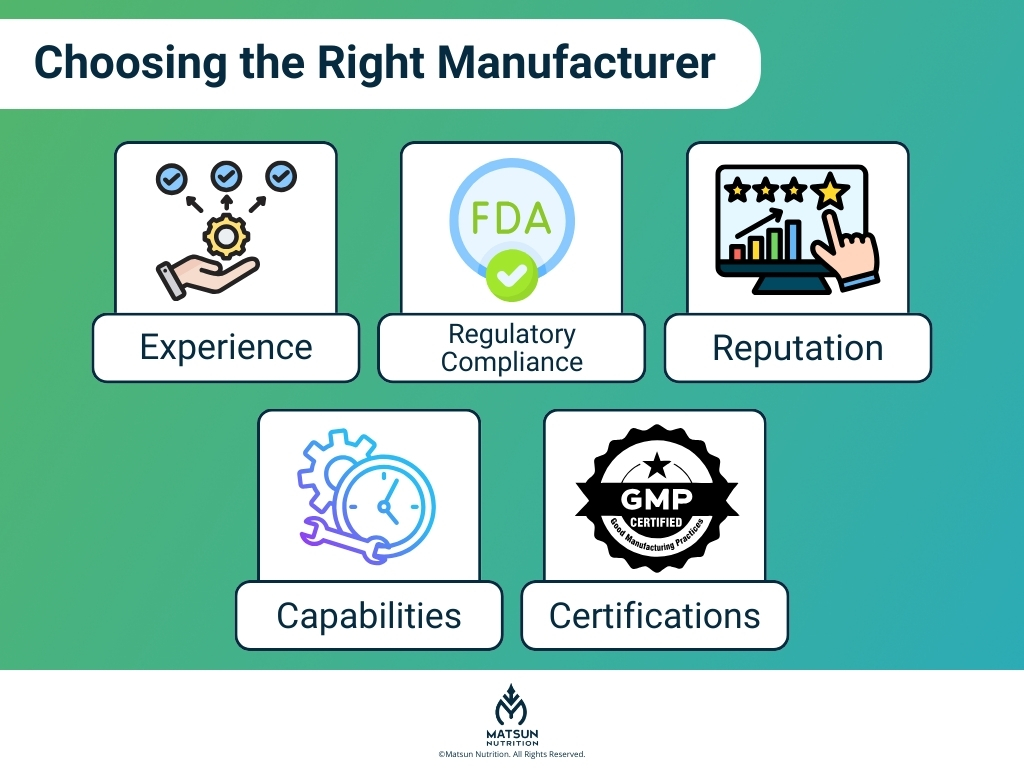

Selecting the right supplement manufacturer paves the way for a successful partnership. While you may not want to spend time assessing various supplement manufacturers, don’t settle for the first manufacturer you come across. Here’s what to look for:

- Experience: Look for a manufacturer with a proven track record in producing high-quality supplements, particularly those in your niche. For instance, if you provide supplements targeting athletes, look for a manufacturer with experience producing performance-enhancing supplements.

- Regulatory compliance: Ensure the manufacturer adheres to US Food and Drug Administration (FDA) regulations and other relevant regulatory requirements for supplements.

- Reputation: Assess the manufacturer’s reputation within the industry. Look for customer testimonials, reviews on third-party review sites and industry awards that demonstrate their commitment to excellence.

- Capabilities: Look for a manufacturer with the equipment and expertise to produce supplements in your desired form (liquids, capsules, powders, etc).

- Certifications: Look for a manufacturer with industry-recognized certifications, such as the USDA Certified Organic certification.

Shortlisting manufacturers that align with your needs helps eliminate potential mismatches and saves valuable time during negotiations. So, don’t hesitate to get in touch with several manufacturers. That said, be wary of manufacturers who make unrealistic claims about production speed and offer suspiciously low prices compared to other manufacturers.

Understanding Your Needs During Supplement Manufacturer Contract Negotiations

Before negotiating, it’s crucial to clearly understand your needs and expectations. This will help you make informed decisions during negotiations, ask the right questions, and close a good deal. Here are key factors to consider when determining your needs:

- Target market: Identify your target customers. For instance, if you want to target people looking to lose weight, you’ll want to partner with a manufacturer with expertise in producing weight loss supplements.

- Product specifications: Identify your product specifications, such as ingredients, dosages, and desired form.

- Production volume: Estimate your initial production needs and projected future growth. This will enable you to determine if the manufacturer can handle increased demand as your business grows.

With a firm understanding of your needs, you’ll be better positioned to negotiate favorable terms with the supplement manufacturer that align with your brand’s values, budget, and long-term strategy.

Key Considerations Suring Supplement Manufacturer Contract Negotiations

The thought of launching your supplement brand can feel like an exciting prospect. However, before you seal the deal with a manufacturer and sign on the dotted line, here are key negotiation points you must address:

1. Pricing and Payment Terms

Negotiating favorable pricing and payment terms is pivotal to the success of your supplement brand. Here are key factors to consider when discussing pricing and pricing terms:

- Pricing models: Most supplement manufacturers offer two pricing models: cost-plus and fixed-fee pricing. In cost-plus or markup pricing, you pay the manufacturer’s production costs plus a markup. Conversely, a fixed fee model establishes a predetermined price for the entire production run. Weigh the pros and cons of each pricing model and choose the one that aligns with your budget, needs, and risk tolerance.

- Transparency: Request a comprehensive breakdown of all the costs involved, such as production, packaging, label design, and shipping. A detailed breakdown of all costs will enable you to understand what you’re paying for, identify potential areas for cost optimization, and discover hidden fees.

- Payment terms: Cash flow is the life of any business because it ensures that operations continue seamlessly. Negotiate payment terms that are favorable for your cash flow, such as payment upon delivery, installation payments, or other flexible payment terms. Consider milestone payments tied to specific product stages.

Finally, negotiate bulk pricing or discounts for large order quantities if you forecast your product demand will rise over time.

2. Minimum Order Quantities (MOQs)

Most supplement manufacturers set minimum order quantities (MOQs) to maintain profitability. However, your brand’s specific needs may not always align perfectly with their minimums.

Discuss the possibility of negotiating flexible MOQs with the manufacturer, particularly if you’re launching a new product or entering a niche market. Request for low MOQs if you’re just starting out but discuss the potential for future volume increases.

RELATED READ:

Read Our Special Guide on “How to find low MOQ Supplement Manufacturers“.

3. Intellectual Property (IP) Rights

Ensure you protect your brand, formula, and proprietary information throughout the manufacturing partnership. Negotiate clear terms that protect your IP rights and prevent the manufacturer from using your proprietary information for their benefit or sharing it with third parties.

If you’re working with a manufacturer to develop new or custom formulations, specify who retains the rights. Ensure there are confidentiality agreements in place, and consider seeking legal advice to clarify and secure these agreements.

4. Quality Control and Regulatory Compliance

Maintaining strict quality control and regulatory compliance is essential for consumer safety and brand reputation. Ensure the contract addresses the following:

- Compliance responsibilities: The contract should clearly outline the manufacturer’s responsibility for complying with all relevant regulatory requirements for producing and labeling supplements.

- Safety: Ensure the manufacturer adheres to GMP (Good Manufacturing Practices) and has a documented quality assurance program.

- Inspection rights: Reserve the right to audit the manufacturer’s facilities and request regular quality reports to verify compliance with quality standards.

5. Term and Termination

Clearly define the contract’s duration and termination conditions. Determine whether it will be renewed automatically or renegotiated after a set period. Consider clauses that allow termination due to non-performance, breach of terms, or changes in business direction.

Ensure the contract outlines a smooth process for transitioning production to another manufacturer if necessary. Having these terms in place minimizes disruption and provides a clear strategy for both parties.

6. Product Liability Insurance

Supplement manufacturing carries potential risks. As a result, it’s essential to protect your brand from potential legal issues. Verify that your manufacturer has sufficient product liability insurance.

Discuss your concerns and ensure their insurance covers third-party claims due to production errors, contamination, or mislabeled products. If needed, negotiate additional coverage specific to your product’s risk level. This coverage is essential for preventing financial losses due to recalls or lawsuits.

7. Dispute Resolution

While you may want your partnership with your manufacturer to go smoothly, disagreements may arise. So, it’s crucial to have measures in place to handle them.

Consider exploring mediation or arbitration, as they are less time-intensive and costly than litigation. Outline which disputes qualify for mediation and specify the rules and location for arbitration. A strong dispute resolution clause can lead to a smoother resolution process and help maintain a healthy working relationship.

Conclusion

Negotiating a supplement manufacturing contract can seem intimidating, but with thorough preparation and a clear understanding of key characteristics, you can navigate the process with confidence.

By selecting a suitable manufacturer and being clear about your production requirements, you lay the groundwork for a successful partnership.

Subsequently, addressing important aspects like pricing, MOQs, intellectual property, quality control, and dispute resolution protects your business interests and helps prevent potential conflicts down the line.

Whether you run a large or small business, we offer flexible contracts with a MOQ of just 12 bottles. Contact us today to schedule a free, no-obligation consultation or get a free quote.

Frequently Asked Questions (FAQs)

The contract should clearly outline procedures for handling production delays. Ideally, it should specify acceptable reasons for delays like ingredient shortages and provide potential remedies, such as revised delivery timelines.

This depends on the terms negotiated in the contract. Some contracts allow formula adjustments with prior notification and approval from the manufacturer, while others may require renegotiation or additional fees for reformulation.

Include clauses that explicitly protect your formulas, trademarks, and proprietary information. Confidentiality agreements should prevent the manufacturer from using or sharing your information. Additionally, clearly specify ownership of any new or custom formulas developed through collaboration.

The contract termination clause should address this scenario. It may specify a notice period before termination and outline procedures for handling unfinished product inventory or transitioning ongoing production to a new manufacturer.

Flexible MOQs help you align production with consumer demand while reducing the risk of overproduction and excess inventory. A manufacturer who understands your scaling strategy will more likely accommodate flexible MOQs.