Launching a vitamin or supplement brand should be exciting, not stressful. But, choosing the wrong vitamin manufacturer can derail your entire product launch, drain your budget, and damage your brand reputation before you even get started.

Whether you’re a startup founder with a groundbreaking formulation or an established brand looking to scale, the manufacturer you choose will make or break your success. One wrong decision can lead to missed deadlines, quality issues, regulatory nightmares, and thousands of dollars down the drain.

Most of these problems are completely avoidable when you know what to watch out for.

In this blog, we’ll walk you through the seven most common (and expensive) mistakes brands make when hiring a vitamin manufacturer, and more importantly, how to avoid them. By the end, you’ll know exactly what questions to ask, what red flags to watch for, and how to find a manufacturing partner who delivers on their promises.

Why Choosing the Right Vitamin Manufacturer Matters

Your manufacturer is your production partner, quality guardian, and often, your formulation consultant all rolled into one. The relationship you build with them directly impacts every aspect of your product’s success.

Your manufacturer controls your product quality, production timelines, regulatory compliance, and ultimately, your brand’s reputation. When customers open that bottle, they’re experiencing the craftsmanship, attention to detail, and quality standards of your manufacturing partner.

A reliable vitamin manufacturer USA partnership means you can focus on growing your brand while they handle production, quality control, and compliance. The wrong choice, however, can lead to product recalls, customer complaints, missed launch dates, and even legal issues.

The stakes are high, which is why understanding these common mistakes is so important.

1. Prioritizing Price Over FDA & GMP Compliance

The cost matters, especially when you’re just starting out. However, the cheapest option almost always costs more in the long run.

Low-cost vitamin manufacturers often cut corners somewhere. Maybe it’s sourcing lower-grade raw materials. Perhaps it’s skipping important testing protocols. Or it could be operating in facilities that barely meet minimum regulatory standards. Whatever the case, these shortcuts eventually catch up with you.

Here’s what can happen when you choose based on price alone:

- Inconsistent product quality batch to batch

- Higher rejection rates during quality testing

- Potential contamination issues

- Regulatory compliance problems

- Damage to your brand reputation when customers notice quality differences

The vitamin and supplement manufacturer you work with should be transparent about their pricing structure. Yes, quality manufacturing costs more upfront, but it saves you from expensive product recalls, legal fees, and the nearly impossible task of rebuilding customer trust after a quality incident.

Instead, ask for detailed quotes that break down exactly what you’re paying for. Ask about raw material sourcing, testing protocols, and quality assurance measures. A manufacturer who’s proud of their quality standards will be more than happy to explain where your investment goes.

2. Skipping the Facility Tour and Audit

Would you hire someone sight unseen? Probably not. Yet many brands sign contracts with liquid vitamin manufacturers without ever visiting their facility or conducting an audit.

This is a huge missed opportunity to verify claims, assess capabilities, and get a real feel for how your products will be made.

Here’s what you should look for during a facility visit:

- Cleanliness and organization of production areas

- Equipment condition and maintenance

- Staff training and professionalism

- Raw material storage conditions

- Quality control laboratory capabilities

- Documentation and record-keeping systems

- Overall operational efficiency

If you’re working with a liquid vitamin manufacturer, pay special attention to their liquid production lines, filling equipment, and bottle cleaning protocols. Liquid formulations require specialized equipment and expertise that not all facilities have.

Can’t visit in person? Request a virtual tour. A reputable manufacturer will accommodate you and show you their facility with pride. If they’re hesitant or refuse, that’s a red flag you shouldn’t ignore.

3. Overlooking NSF-Certified Vitamin Manufacturing Standards

GMP certification is essential. Good Manufacturing Practices (GMP) are the baseline standards that ensure your products are consistently produced and controlled according to quality standards.

However, not all GMP certifications are created equal. The FDA recognizes different levels, and some manufacturers display expired certificates or certifications that don’t actually cover dietary supplements.

Here are some essential certifications to verify:

- Current FDA-registered facility status

- NSF or NPA GMP certification for dietary supplements

- Organic certifications (USDA, if applicable)

- Kosher or Halal certifications (if needed for your market)

- Third-party testing partnerships or in-house laboratory accreditation

Ask to see actual certificates and verify certification numbers with the issuing organizations. This might seem tedious, but it protects you from partnering with facilities that can’t legally manufacture supplements to proper standards.

Third-party testing is equally important. The best vitamin manufacturer USA facilities either conduct in-depth in-house testing or partner with accredited third-party labs to verify potency, purity, and absence of contaminants. Don’t assume testing happens, ask for specifics about their testing protocols.

4. Choosing MOQs That Don't Match Your Startup Growth

Nothing kills a startup’s cash flow faster than being forced to order 10,000 units when you can only sell 1,000 in your first year.

Minimum order quantities exist for good reasons. They help manufacturers operate efficiently and keep costs manageable. But MOQs that don’t align with your business stage and sales projections create serious problems.

Here are some common problems with MOQs:

- Tying up capital in excess inventory

- Risk of product expiration before you can sell through

- Storage costs eating into margins

- Inability to pivot or adjust formulations based on market feedback

- Cash flow problems that prevent you from investing in marketing and growth

Some vitamin manufacturers work exclusively with large brands and have MOQs in the tens of thousands. Others, like low MOQ supplement manufacturers, specialize in smaller batches perfect for startups and emerging brands.

You should always be honest about your sales projections and growth timeline. Look for manufacturers who offer flexible MOQs that match your current stage while allowing you to scale up as you grow. Some facilities offer tiered pricing, for example, higher per-unit costs for smaller batches that decrease as your volume increases.

5. Failing to Clarify Formulation Support and Intellectual Property Rights

You have a brilliant idea for a vitamin blend, but you’re not a formulation chemist. Who’s responsible for turning your concept into a stable, effective, marketable product?

This is where formulation support becomes critical, and where things can get complicated fast if expectations aren’t clear upfront.

Here are key formulation questions to address:

- Does the manufacturer offer formulation assistance or do you need to provide a complete formula?

- Who owns the formulation? You or the manufacturer?

- Can they help source hard-to-find ingredients?

- Will they advise on dosing, delivery formats, and stability?

- What happens if you want to switch manufacturers later?

Some vitamin supplement manufacturers excel at formulation support, offering experienced teams who can translate your wellness goals into effective products. Others expect you to arrive with a complete, production-ready formula.

Neither approach is wrong, but mismatched expectations cause serious problems. Imagine investing months in formulation development with one manufacturer, only to discover they own the formula and you can’t take it elsewhere.

Get everything in writing. Ensure your contract clearly states intellectual property ownership, confidentiality agreements, and whether you’re free to manufacture your formula elsewhere if needed. If formulation support is promised, define the scope: How many iterations are included? What’s the timeline? Who pays for stability testing?

6. Not Verifying Production Capacity and Timeline Reliability

Your manufacturer says they can handle your order and deliver in six weeks. Fast forward two months: you’re still waiting, your launch date has passed, and you’ve got frustrated customers asking where their pre-ordered products are.

Production delays are one of the most common complaints brands have about their manufacturers, and one of the most damaging to your business.

Here’s why production problems happen:

- Manufacturer is overcommitted and can’t keep up with demand

- Equipment breakdowns without backup systems

- Raw material sourcing delays

- Understaffing during busy seasons

- Poor project management and communication

When vetting vitamin manufacturers, dig deep into their capacity and reliability track record. How many brands do they currently work with? What’s their typical production schedule? Do they have backup equipment? How do they handle rush orders or seasonal demand spikes?

Here are red flags to watch for:

- Vague timelines without specific milestones

- Reluctance to commit to deadlines in writing

- No clear communication protocol during production

- History of last-minute delays (check references!)

- Operating at maximum capacity with no buffer

Ask for references from current clients, specifically asking about timeline reliability. Were deadlines met? How was communication? How did they handle unexpected issues?

If you’re manufacturing specialty products like liquid vitamins, understand that liquid production often requires different timelines than capsules or tablets. A custom liquid vitamin manufacturer should be able to provide realistic timeframes based on their specific equipment and processes.

7. Neglecting to Define Communication Protocols and Problem-Solving Processes

Imagine it’s day 35 of your 42-day production timeline. You reach out for an update and… silence. You try again. Nothing. You finally get someone on the phone three days later, only to learn there’s been a problem for a week that nobody told you about.

Poor communication destroys manufacturing relationships faster than almost anything else.

The best vitamin manufacturer partnerships are built on transparent, proactive communication. You should never have to wonder what’s happening with your production run or feel like you’re bothering them by asking for updates.

Establish clear expectations upfront by asking these questions:

- Who is your primary point of contact?

- How quickly can you expect responses to emails and calls?

- Will you receive proactive updates at production milestones?

- What happens if problems arise and how quickly will you be notified?

- How are change orders or formula adjustments handled?

- What’s the escalation process if your contact isn’t available?

This might seem overly detailed, but these conversations prevent countless headaches later. When everyone knows the communication protocol, there’s accountability on both sides.

Ask about their typical client communication approach. Do they assign dedicated account managers? Is there an online portal where you can track production status? How do they handle after-hours emergencies?

A professional vitamin and supplement manufacturer will appreciate your thoroughness here because it shows you’re a serious business partner who values clear processes.

How to Identify the Best Vitamin Manufacturer in the USA

Now that you know the mistakes to avoid, let’s talk about what to actually look for in a manufacturing partner.

Start with credentials and compliance: Verify GMP certification, FDA registration, and any specialty certifications relevant to your products (organic, non-GMO, vegan, etc.). These are must-haves.

Evaluate their expertise in your product category: Not all manufacturers are good at everything. Some specialize in capsules and tablets but struggle with liquids. Others excel at organic formulations but don’t handle synthetic ingredients. If you’re creating a unique product format, work with someone who has proven expertise in that area.

Assess their formulation capabilities: Do they just manufacture what you give them, or can they help you develop and optimize formulas? Access to experienced formulators can be invaluable, especially if you’re new to the supplement industry.

Review their testing and quality protocols: Ask for detailed information about their testing procedures, both in-process and finished product. How do they verify potency? What contaminant testing do they conduct? How often do they test equipment and environments?

Consider their flexibility and scalability: Can they grow with you? Today you might need 1,000 units, but what happens when you need 50,000? The best partnerships allow you to start small and scale seamlessly as your brand grows.

Evaluate communication and culture fit: You’ll be working closely with this team, possibly for years. Do their communication style and values align with yours? Do they seem genuinely interested in your success, or just in making a sale?

Check references thoroughly: Don’t just look at testimonials on their website. Ask for direct references from current clients with similar production needs. Ask specific questions about quality, reliability, communication, and problem-solving.

When evaluating options to manufacture vitamins, create a scorecard that weights these factors according to your priorities. This helps you compare options objectively rather than getting swayed by a slick sales pitch or low price alone.

Understanding Different Manufacturing Models

As you research potential partners, you’ll encounter different manufacturing models. Understanding these helps you choose the right fit for your brand.

1. Private Label Manufacturing

You select from the manufacturer’s existing formulas and put your label on them. This is the fastest, easiest, and often most affordable option. Perfect if you’re testing the market or want to launch quickly without custom formulation. However, your products won’t be unique, so competitors could sell identical formulas under different brands.

2. Custom Manufacturing

You work with the manufacturer to develop a proprietary formula specifically for your brand. This requires more time, investment, and often higher MOQs, but results in truly unique products that differentiate your brand. You own the formulation (if your contract says so), giving you a competitive advantage.

3. Contract Manufacturing

You own the formula and intellectual property, and the manufacturer simply produces according to your specifications. This gives you maximum control but requires you to already have a production-ready formula and often more technical knowledge about manufacturing processes.

Each model has trade-offs. Private label gets you to market fastest but offers the least differentiation. Custom manufacturing balances speed, cost, and uniqueness. Contract manufacturing gives you complete control but requires more expertise and involvement.

Choose based on your goals, timeline, budget, and competitive landscape. For many brands, starting with private label or custom manufacturing and eventually moving to contract manufacturing as you scale makes the most sense.

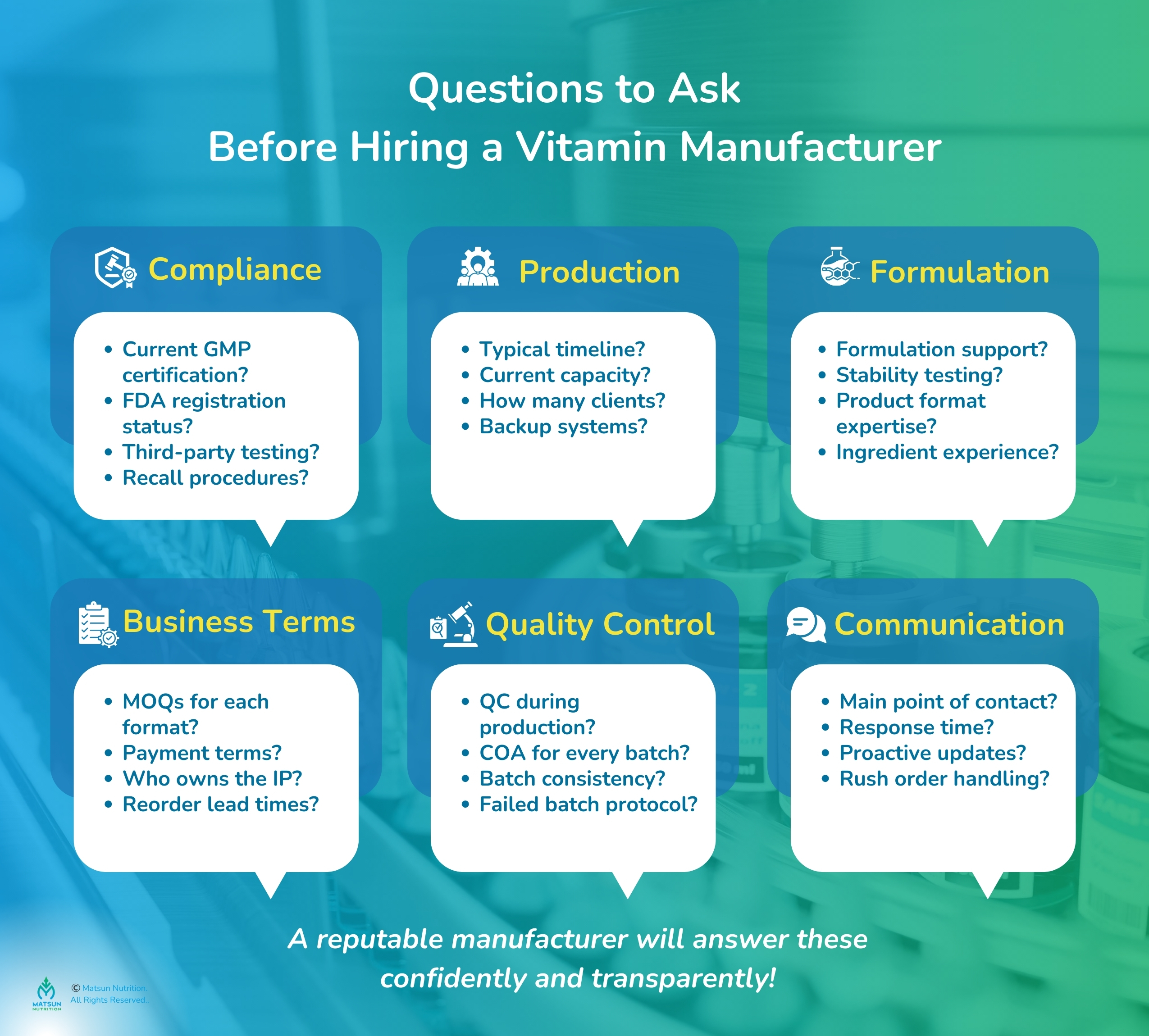

Questions to Ask Before Signing a Contract Vitamin Manufacturer

Armed with everything you now know, here are the critical questions to ask every potential vitamin manufacturer before signing on the dotted line:

Certifications and Compliance:

- Can I see your current GMP certification and FDA registration?

- When was your last facility inspection and what were the results?

- What third-party testing do you conduct on raw materials and finished products?

- How do you handle recalls or quality issues if they arise?

Production and Capacity:

- What’s your typical production timeline from order to delivery?

- How many brands are you currently manufacturing for?

- What’s your capacity, and how much buffer do you maintain? 8. How do you handle seasonal demand fluctuations?

Formulation and Products:

- Do you offer formulation support, and what does that include?

- Can you provide stability testing and shelf-life studies?

- What product formats do you specialize in (capsules, tablets, liquids, powders, gummies)?

- Do you have experience with [specific ingredients or delivery systems]?

Business Terms:

- What are your MOQs for different product formats?

- What’s your payment schedule and terms?

- Who owns the formulation intellectual property?

- What are your lead times for reorders?

About Quality and Testing:

- What quality control measures are in place during production?

- Can I receive certificates of analysis for every batch?

- How do you ensure batch-to-batch consistency?

- What happens if a batch fails quality testing?

About Communication and Support:

- Who will be my main point of contact?

- How quickly do you typically respond to inquiries?

- Will I receive production updates without having to ask?

- How do you handle change orders or rush requests?

Don’t feel awkward asking these questions. Any reputable manufacturer expects them and should answer confidently and transparently. Hesitation, vague answers, or defensiveness are red flags that should make you reconsider the partnership.

Red Flags That Should Make You Walk Away

Sometimes the best decision is knowing when to say no. Here are warning signs that should make you seriously reconsider a potential manufacturing partner:

They can’t or won’t provide current certifications. GMP certification and FDA registration are non-negotiable. If they can’t produce current certificates immediately, walk away.

They promise unrealistically fast timelines. If everyone else quotes 8-10 weeks and one manufacturer promises 3 weeks, something’s wrong. They’re either overpromising to get your business or cutting corners somewhere.

They’re unwilling to put terms in writing. Everything important should be in your contract: timelines, quality standards, IP ownership, MOQs, pricing. If they resist putting promises in writing, they don’t intend to keep them.

They have no references or won’t provide them. Established manufacturers should easily provide multiple references from satisfied clients. If they can’t or won’t, that tells you something.

They’re dismissive of your questions or concerns. You’re trusting them with your brand’s reputation. They should welcome your questions and provide thorough answers. Dismissiveness or impatience during the vetting process will only get worse once you’re a client.

Their facility is disorganized or dirty. This is why facility visits matter. A cluttered, poorly organized, or unclean facility indicates poor quality control and operational management.

They pressure you to sign immediately. Legitimate manufacturers understand that choosing a partner is a major decision. High-pressure sales tactics suggest they need business badly, which might mean they’re struggling for good reasons.

They can’t clearly explain their quality processes. If they can’t articulate their testing protocols, quality control measures, and how they ensure consistency, they probably don’t have robust systems in place.

Trust your instincts. If something feels off, it probably is. There are plenty of excellent manufacturers out there, so don’t settle for one that raises concerns.

Final Checklist Before Hiring a Vitamin and Supplement Manufacturer

Before you make your final decision, run through this checklist to ensure you’ve covered all your bases:

- Verified current GMP certification and FDA registration

Confirmed these are active, current, and specific to dietary supplements.

2. Conducted facility visit or virtual tour

Assessed cleanliness, organization, equipment, and overall operations.

3. Checked references from current clients

Spoke directly with brands about their experience with quality, timelines, and communication.

4. Confirmed MOQs align with your business stage

Ensured minimum orders don’t tie up excessive capital or create excess inventory.

5. Reviewed and understood all contract terms

Everything important is in writing, including timelines, quality standards, IP ownership, and pricing.

6. Clarified formulation support and IP ownership

You know exactly who owns your formula and what support you’ll receive.

7. Established clear communication protocols

You know who your contact is, response time expectations, and the update process.

8. Confirmed their capacity and timeline reliability

They can handle your production needs both now and as you scale.

9. Reviewed their testing and quality control procedures

You understand exactly how they ensure product quality and consistency.

10. Assessed culture and values alignment

Their communication style and business values align with yours.

11. Compared pricing transparently

You understand what you’re paying for and how pricing compares to other options.

12. Planned for growth and scaling

They can accommodate increased volume as your brand expands.

If you can check every box with confidence, you’ve found a potential winner. If there are gaps, talk about them before signing anything.

Building a Long-Term Partnership

The best relationships between brands and vitamin manufacturers are collaborative, transparent, and mutually beneficial. Your manufacturer should feel invested in your success, not just interested in your purchase orders.

Here’s how to nurture a strong partnership:

Communicate proactively. Don’t wait for problems to arise. Keep your manufacturer informed about your marketing plans, anticipated demand increases, and any changes in your business that might affect production needs.

Honor your commitments. If you commit to an order, follow through. If you establish payment terms, meet them. Manufacturers deal with countless brands, and being reliable and professional makes you a valued client.

Provide feedback. When things go well, let them know. When problems arise, address them directly and constructively. Good manufacturers want to improve and will appreciate honest feedback.

Plan ahead. Last-minute rush orders are expensive and stressful for everyone. Plan your production schedule as far in advance as possible, considering lead times, seasonal demand, and growth projections.

Be reasonable. Understand that manufacturing is complex. Equipment breaks, supply chains have hiccups, and unexpected issues arise. How your manufacturer handles these situations matters more than whether they happen at all.

The brands that succeed long-term are those that view their manufacturer as a true partner, not just a vendor. Invest in that relationship, and it will pay dividends for years to come.

Ready to Find Your Perfect Manufacturing Partner?

vitamin manufacturerChoosing a vitamin manufacturer is one of the most important decisions you’ll make for your supplement brand. The manufacturer you select impacts your product quality, customer satisfaction, brand reputation, and ultimately, your success in this competitive market.

By avoiding these seven costly mistakes, you’re already ahead of most new brands. You know what to look for, what questions to ask, and what red flags to watch for. You understand that the cheapest option isn’t the best option, that certifications matter, and that communication can make or break a manufacturing relationship.

Take your time with this decision. Visit facilities, check references, ask tough questions, and trust your instincts. The right manufacturing partner is out there, one who shares your commitment to quality, operates with transparency, and genuinely wants to help your brand succeed.

Ready to work with a vitamin manufacturer who answers these questions with confidence and transparency? At Matsun Nutrition, we’re committed to quality, compliance, and partnership. Whether you’re looking for custom formulation support, flexible MOQs for emerging brands, or specialized capabilities like liquid vitamin manufacturing, we’re here to help. Explore our vitamin manufacturing services, check out our low MOQ options, or learn more about our liquid vitamin manufacturing capabilities. Let’s build something great together!

Frequently Asked Questions

What should I look for in a vitamin manufacturer?

Look for current GMP certification, FDA registration, transparent quality control processes, appropriate MOQs for your business stage, strong communication, and positive references from current clients. Visit their facility if possible, verify their certifications independently, and ensure their expertise aligns with your product needs. A good manufacturer should be transparent about their processes and willing to answer all your questions thoroughly.

How do I know if a vitamin manufacturer is GMP certified?

Ask to see their actual GMP certificate, not just a logo on their website. Verify the certificate is current (not expired) and issued by a recognized third-party organization like NSF or NPA. Confirm their FDA registration number and check it against the FDA’s database. During a facility visit or audit, look for evidence that GMP practices are actively followed, not just claimed on paper. Request documentation of their most recent third-party audits.

Is it better to work with a vitamin manufacturer in the USA?

Working with a USA-based manufacturer offers several advantages: easier facility visits and audits, better communication without language or time zone barriers, more stringent regulatory oversight by the FDA, typically higher quality standards, and stronger intellectual property protections. Domestic manufacturing also often means shorter supply chains, faster response times to issues, and easier relationship building. However, the best choice depends on your specific needs, budget, and market.

What is a reasonable MOQ when choosing a manufacturer?

Reasonable MOQs vary greatly depending on product type, complexity, and the manufacturer’s focus. For startups and small brands, look for manufacturers offering MOQs between 500-2,500 units. Mid-sized brands might handle 5,000-10,000 units. Large-scale manufacturers often require 10,000+ units. The “right” MOQ matches your sales projections and cash flow—don’t overextend yourself. Some manufacturers specialize in low MOQs specifically for emerging brands, which can be ideal when you’re starting out.

How long does vitamin manufacturing usually take?

Typical manufacturing timelines range from 6-12 weeks from order confirmation to delivery, though this varies based on product complexity, ingredient availability, and the manufacturer’s current workload. Custom formulations requiring stability testing may take 12-16 weeks or longer initially. Private label products from existing formulas can be faster, sometimes 4-6 weeks. Always add buffer time to your timeline for unexpected delays. Rush production is sometimes available but costs significantly more and isn’t always possible.

What’s the difference between private label and custom vitamin manufacturing?

Private label means selecting from the manufacturer’s existing formulas and putting your brand name on them. Custom manufacturing involves developing a proprietary formula specifically for your brand, resulting in unique products but requiring more time, investment, and often higher MOQs. Private label gets you to market quickly; custom manufacturing creates competitive differentiation. Many brands start with private label to test the market, then develop custom formulas once they’ve established demand.

Can one manufacturer handle liquids, capsules, and powders?

Some full-service manufacturers can produce multiple formats, but many specialize in specific delivery systems. Liquid manufacturing requires very different equipment and expertise than capsule or tablet production. If you need multiple formats, specifically ask about their capabilities for each. Be wary of manufacturers who claim to do everything but don’t have specialized equipment or experienced teams for each format. Often, working with specialists for complex products like liquids while using a different manufacturer for capsules yields better results.

How important is formulation support when manufacturing vitamins?

Formulation support is crucial if you’re not working with a professional formulator. Experienced manufacturers can help optimize dosing, improve stability, select appropriate delivery formats, source quality ingredients, and ensure your formula is production-ready. This expertise prevents costly reformulation delays and quality issues. Even if you have a general concept, manufacturer formulation support can refine it into a marketable, stable, effective product. However, ensure your contract clearly states who owns the intellectual property for any formulas developed together.

What questions should I ask before signing a manufacturing contract?

Ask about current certifications, typical production timelines, MOQs, formulation support availability, intellectual property ownership, testing protocols, quality control measures, communication processes, payment terms, and capacity to handle your growth. Request references and speak directly with current clients about their experiences. Clarify what happens if quality issues arise, how change orders are handled, and what the process is for scaling up production. Ensure all critical terms and promises are written into your contract.

How do I avoid common supplement manufacturing mistakes?

Do thorough due diligence before selecting a manufacturer: verify certifications independently, visit facilities, check references, and ask detailed questions about every aspect of production. Don’t choose based on price alone, evaluate quality, reliability, and communication. Start with realistic MOQs that match your business stage. Get everything in writing in your contract. Establish clear communication protocols from the start. Build a true partnership by being professional, honoring commitments, and maintaining open dialogue. Plan production well in advance and build buffer time into your timelines.