The demand for supplements is surging, creating a massive opportunity for brands. But success starts with the right partner. When evaluating supplement contract manufacturing, the choice comes down to quality, location, and risk. Making the wrong choice can jeopardize your entire brand. In the U.S., approximately 75% of adults take dietary supplements, with 55% using them regularly. This surge in demand creates a unique opportunity for brands to thrive in the supplements industry.

At Matsun Nutrition, we define the advantages: we are your trusted USA Supplement Contract Manufacturer offering incredibly low MOQs to accelerate your launch. This definitive guide details the 10 proven benefits—from cost control to compliance—that only an experienced, full-service partner can guarantee.

What Is a Supplement Contract Manufacturer?

Raising the capital to build a manufacturing facility to manufacture supplements can be tough if you want to start a supplement brand. That’s where a supplement contract manufacturer comes in.

A supplement contract manufacturer is a company that can relieve you from the hassle of manufacturing supplements by producing them on your behalf. A dietary supplement manufacturer can also help you with other essential tasks, including custom formulation, supplement packaging, and labeling.

10 Core Benefits of Supplement Contract Manufacturing

By partnering with a strategic manufacturing partner, businesses gain significant competitive advantages. We’ve prioritized these 10 benefits to highlight where your investment yields the greatest returns.

1. Lower Initial Costs & Eliminated Capital Investment

You avoid the massive cost of building a facility, buying equipment, and hiring staff, allowing you to focus funds on marketing and branding.

2. Low Minimum Order Quantities (Low MOQs) for Reduced Risk

Unlike high-MOQ facilities, contracting with a flexible manufacturer allows you to start production with small batches. This minimizes inventory risk and frees up capital, enabling quick market testing and faster product refinement.

3. Ensuring Quality Control in Dietary Supplement Production

Reputable USA Supplement Contract Manufacturers are FDA-registered and adhere strictly to cGMP standards. Supplements should be third-party tested by organizations like the NSF to guarantee safety and efficacy.

4. Accelerate Speed to Market with Contract Manufacturing

With nearly 30,000 different brands available, speed is essential. Manufacturers have the expertise to produce supplements faster, giving your brand a huge differentiator in the market.

5. Scalable Solutions for Nutritional Supplement Businesses

Easily increase or decrease production based on product demand without the worry of purchasing extra equipment or underutilizing labor.

6. Custom Formulations for Niche Dietary Supplement Markets

A contract manufacturer provides expert R&D to produce tailor-made supplements. This includes specialized support for high-demand formats like liquids, custom powders, and functional gummies.

7. Turnkey Contract Manufacturing for Streamlined Operations

Choose partners who handle the entire process from concept to delivery—product formulation, manufacturing, label design, packaging, and order fulfillment.

8. Reduced Labor and Overhead Costs

Tap into a large, established talent pool (QA specialists, food scientists, and machine operators) without the burden of hiring, payroll, or staff management.

9. Accurate Cost Estimates for Supplement Manufacturing Projects

Eliminate the guesswork. Contract manufacturers provide detailed, transparent upfront quotations, allowing for accurate budgeting across raw materials, testing, and compliance.

10. Leverage Established Supplier Relationships

Contract manufacturers negotiate volume-based discounts and secure stable pricing terms, enhancing your operational efficiency and protecting you from raw material price fluctuations.

RELATED READ:

How to find Low MOQ Supplement Manufacturer for SMEs

The Hidden costs of low quality supplement manufacturing services.

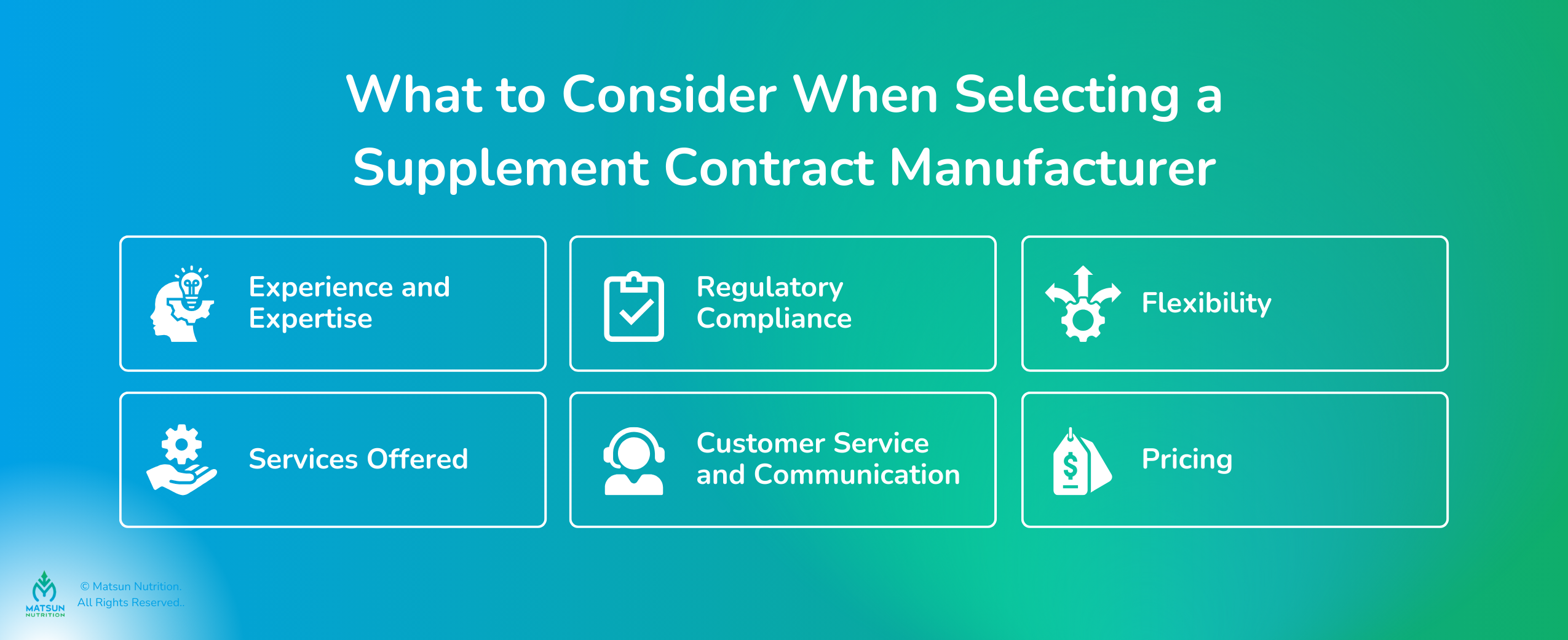

What to Consider When Selecting a Supplement Contract Manufacturer

While working with a supplement contract manufacturer offers many benefits, not all manufacturers are created equal. Bearing that in mind, here are key factors to consider when selecting a manufacturer:

1. Experience and Expertise

Look for a dietary supplement manufacturer with a track record of producing supplements in your specific product category, especially complex liquid supplements or specialized functional powders.

2. Regulatory Compliance

Choose a manufacturer with certifications from reputable bodies, such as the FDA registration, cGMP compliance, and third-party certifications like NSF or USDA Organic.

3. Flexibility (Low MOQs and Scalability)

(Emphasize) Select a manufacturer that not only offers low minimum order quantities (MOQs) for launch but also has the capacity to scale production rapidly as your demand rises.

4. Comprehensive Services Offered

Choose a manufacturer that offers end-to-end solutions (formulation, packaging, fulfillment) to centralize and accelerate the entire production process.

5. Customer Service and Communication

Demand transparency in sourcing and quality standards. Partner with a manufacturer that provides reliable communication and quick responses to queries.

Partner With a Reputable Contract Manufacturer to Streamline Production

Working with a contract manufacturer to produce supplements allows you to concentrate on aspects of your business you’re conversant with while the manufacturer handles the technical aspects of production. Choose a reputable manufacturer that’s flexible, adheres to regulatory guidelines, and has experience producing your desired supplements.

At Matsun Nutrition, we have over three decades of experience producing a variety of supplements, and we are FDA-inspected and cGMP-compliant. Moreover, we offer ultra-low minimums of just 12 bottles, enabling small businesses to launch with minimal risk.

Ready to start offering consumers high-quality supplements? Contact us today to learn why you should partner with us for supplement contract manufacturing.

Frequently Asked Questions

What is the typical minimum order quantity for supplements?

The typical minimum order quantity (MOQ) across the supplement industry is high, usually ranging from 2500 units per formula. However, at Matsun Nutrition, we specialize in supporting emerging brands. We offer one of the lowest entry points in the market, with MOQs starting as low as 12 bottles for select stock formulas, significantly reducing your initial investment risk.

What is the cost difference for USA contract manufacturing?

While the per-unit cost for USA contract manufacturing may initially be higher than overseas options, the true long-term value is superior. You save money by eliminating risks like customs delays, shipping fees, communication errors, and regulatory non-compliance. Partnering with Matsun means investing in guaranteed FDA-registered facilities and cGMP-certified quality, which ultimately protects your brand’s reputation and profits.

Are liquid supplements harder to manufacture than pills?

Yes, liquid supplements are generally more complex to manufacture than pills or powders. Liquids require specialized equipment for precise blending, complex stabilization strategies to ensure a long shelf-life, and advanced formulation to mask strong flavors without compromising efficacy. Matsun Nutrition has over three decades of expertise in liquid supplement manufacturing, giving us the unique technical capability to handle these challenges and deliver stable, palatable, and effective liquid products.