Speed is of the essence in the vitamin and supplement industry. Whether you’re launching a new supplement brand or replenishing an existing one, having a reliable supply chain is crucial.

By choosing a contract vitamin manufacturer that offers fast lead times, you can meet market demand quickly and stay ahead of the competition. However, not all contract manufacturers are created equal. That’s why when speed is a priority, choosing the right partner is essential.

In this blog post, we’ll provide tips on finding a contract vitamin manufacturer who offers fast lead times without compromising on product quality.

Why Fast Lead Times Matter in Vitamin Manufacturing

The demand for vitamins and dietary supplements can fluctuate rapidly, influenced by various factors such as seasonal changes, health trends, and marketing campaigns. That’s why, as a brand owner, getting your product to market fast is crucial.

That said, here are some benefits of fast lead times in vitamin manufacturing:

1. Capitalize on Market Trends

The health and wellness industry is dynamic. Consumer tastes and preferences shift rapidly. By launching new products quickly, you can capitalize on emerging market needs and establish your brand as a leader in the space. This ”first-to-market” advantage can be especially invaluable for attracting early adopters and building brand loyalty.

2. Respond to Seasonal Demands

Vitamin and supplement sales often fluctuate based on seasonal trends. For instance, demand for immunity boosters often spikes during the cold and flu season. With fast lead times, you can respond to seasonal fluctuations efficiently.

3. Respond to Competitor Activity

The vitamin and dietary supplements industry is incredibly competitive, with companies releasing new formulas every so often. The Food and Drug Administration (FDA) estimates supplement manufacturers release around 1,000 new supplements yearly. Reacting quickly to competitor activity can give you a significant advantage over other brands, allowing you to stay ahead of the pack.

4. Maintain a Steady Inventory Flow

Stockouts can significantly affect your profitability and damage customer satisfaction. With fast lead times, you can minimize the risk of running out of popular products and ensure that products are consistently available to customers, enhancing customer satisfaction.

5. Lower Inventory Costs

Long lead times may compel you to maintain excess inventory to meet demand fluctuations. Shortening lead times can reduce inventory costs and free up cash for other business needs.

6. Flexibility in Production Planning

Shorter lead times allow for more flexible production planning, making adjusting production volumes or schedules based on product demand easier.

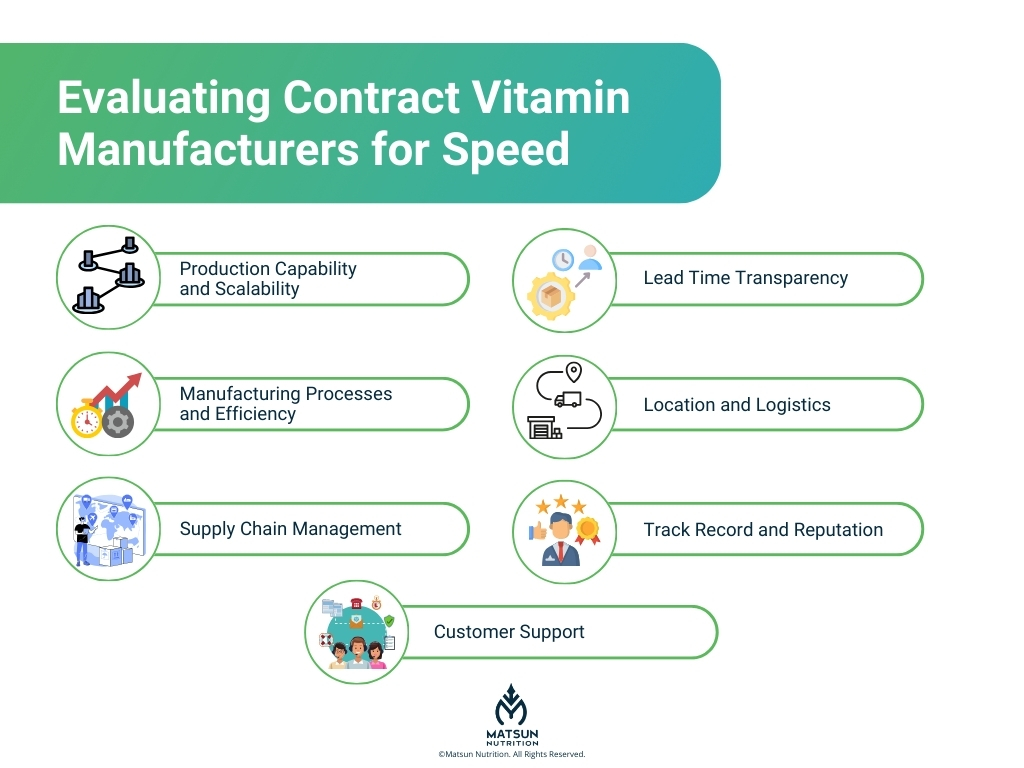

Evaluating Contract Vitamin Manufacturers for Speed

Selecting the right contract manufacturer for your vitamin production is a critical decision that can significantly impact your business’s success. When it comes to speed, not all manufacturers are created equal.

Here are key factors to consider when assessing contract vitamin manufacturers for their ability to deliver fast lead times:

1. Production Capability and Scalability

Evaluate the manufacturer’s production capability and scalability. Do they have the ability to handle your projected order volumes? Look for a manufacturer with the flexibility to rapidly scale production up or down in response to demand fluctuations.

Additionally, if you want to create a custom formulation, inquire about the time the manufacturer takes to develop and test the formula, as custom formulas often require more production time.

2. Manufacturing Processes and Efficiency

Investigate the manufacturing processes employed by the manufacturer. Are they streamlined and efficient? Lean manufacturing principles can help reduce costs, minimize waste, and improve product quality. Ask about their equipment, technology, and automation capabilities to ensure efficient operations.

3. Supply Chain Management

A streamlined supply chain is vital for fast lead times. Inquire about the manufacturer’s relationships with raw material suppliers and their ability to obtain ingredients promptly. An integrated supply chain with reliable suppliers can help minimize delays and ensure a smooth production process.

Additionally, if your formula requires a rare ingredient, inquire about the manufacturer’s ability to source rare ingredients, as their scarcity can impact lead times.

4. Lead Time Transparency

Transparency is critical when it comes to lead times. A reputable contract manufacturer should be upfront about their lead times for various stages of the production process, from ingredient sourcing and processing to order fulfillment. Visibility into the production timeline can help you plan effectively and avoid surprises.

5. Location and Logistics

Consider the location of the manufacturer’s facility and their logistics capabilities. Proximity to major transportation hubs and distribution centers can help minimize transit times and expedite product delivery. Additionally, inquire about the manufacturer’s shipping options and partnerships with logistics providers to ensure efficient delivery of your products.

6. Track Record and Reputation

Research the contract manufacturer’s track record and reputation in the industry. Look for testimonials, case studies, or references from past clients to assess their reliability and performance. Also, check reviews on third-party review sites like Google, Yelp, and Angi.

A manufacturer with many favorable reviews and a proven track record of delivering fast lead times is more likely to meet your expectations.

7. Customer Support

Assess the manufacturer’s level of customer support and communication. Are they available via your preferred communication channels? Are they responsive to inquiries and proactive in addressing concerns?

A manufacturer that’s available on various channels and responsive will ensure any issues or delays are promptly addressed, ensuring your business operations proceed smoothly.

Other Considerations Beyond Speed

While fast lead times are crucial, they shouldn’t be the sole factor when choosing a contract vitamin manufacturer. Here are some additional considerations to keep in mind to ensure a successful partnership:

8. Quality Assurance and Regulatory Compliance

Rigorous quality control procedures are critical to product efficacy and safety. Choose a manufacturer that adheres to strict quality control standards and complies with regulatory requirements such as Good Manufacturing Practices (GMP).

Additionally, choose a manufacturer with relevant certifications, such as the USDA Organic Certification, as certifications demonstrate a commitment to quality.

9. Flexibility

Look for a manufacturer that’s ready to accommodate your specific needs. Whether it’s packaging preferences, label design, or fulfillment, a flexible manufacturer can adapt to your requirements and provide tailor-made solutions to support your brand’s success.

10. Minimum Order Quantities

Most contract vitamin manufacturers have minimum order quantities (MOQs) to cover their production costs and ensure they remain profitable. MOQs are the minimum amount of product they’re willing to produce per order.

While some manufacturers have low MOQs, others have high ones that can impact lead times. Consider your anticipated production volume and choose a manufacturer with MOQs that align with your needs. If you’re launching a new product and require smaller batches to test the market, look for manufacturers offering low MOQs.

11. Cost and Value

Speed often comes at a premium, as manufacturers that offer fast lead times may cost more than their counterparts. Conduct a cost-benefit analysis when comparing manufacturers. A manufacturer that offers competitive pricing without compromising on quality can help you maximize your profitability while delivering high-quality products to your customers.

Choose a Contract Vitamin Manufacturer With Flexible MOQs

Selecting a contract vitamin manufacturer with fast lead times is critical to the success of your supplements business. However, speed is just one piece of the puzzle. By prioritizing speed and quality, you can ensure a smooth and successful product launch, maintain a steady inventory flow, and stay ahead of other supplement brands in the competitive health and wellness industry.

At Matsun Nutrition, we can help you get your products to market fast without compromising on quality control testing procedures. And best of all? We offer flexible MOQs with an incredibly low minimum MOQ of just 12 bottles! So, you won’t have to purchase excess inventory, freeing up capital for other essential business expenses like wages, advertising, and utilities.

Ready to get your product on store shelves or online promptly? Contact us today to learn more about our lead times or get a free quote.

Frequently Asked Questions (FAQs)

While some manufacturers may offer rapid turnaround times, be wary. Prioritizing speed over rigorous quality control procedures can lead to serious issues, such as hefty losses due to product recalls or even legal trouble. So, focus on finding a manufacturer that offers reasonable turnaround times without compromising quality.

Creating custom formulations can increase the time it takes to get your product to market, as custom formulations require product development from scratch. Discuss your needs with potential manufacturers to establish their average turnaround time for custom formulations.

Discuss your desired packaging options with shortlisted manufacturers. Some have in-house packaging capabilities, while others might outsource it. Inquire about lead times for outsourced packaging to ensure it doesn't significantly impact your lead times.

Not all contract vitamin manufacturers cater to small production runs. If you're launching a new product or brand, choose a manufacturer with a low MOQ. However, choose one that can scale production as your business grows and product demand increases.

Production needs may change as your business grows and consumer preferences change. Look for a manufacturer that's willing to accommodate changing production needs. A flexible partner can adjust production volumes, formulations, and schedules to meet your dynamic requirements and promote your brand's growth.