Choosing the right herbal supplement manufacturer is crucial for your brand to succeed. Whether you’re launching your first product line or switching from a manufacturer that’s let you down, the questions you ask upfront determine everything, from product quality to customer satisfaction to your bottom line.

The herbal supplement industry is competitive, and not all manufacturers are the same. Some cut corners on quality. Others overpromise and underdeliver on timelines. And far too many leave you guessing about what’s really happening with your product during production.

If you’re looking for the best herbal supplement manufacturers or specifically a herbal supplement manufacturer USA-based, you need a clear vetting process. The right questions separate the professionals from the pretenders, helping you find a manufacturing partner who understands your vision and can deliver on it consistently.

In this blog, we’ll walk you through the essential questions to ask before signing any contract or placing your first order. These are the make-or-break questions that separate a great manufacturing partner from one that’ll cost you down the line.

Essential Questions for Herbal Makers to Answer

Before diving into technical specifics, start with the big-picture questions that reveal whether a manufacturer is the right fit for your business.

How long have you been manufacturing herbal supplements?

Experience matters. While newer manufacturers can certainly deliver quality, established companies bring proven processes, regulatory knowledge, and problem-solving expertise that only comes from years in the industry.

What types of brands do you typically work with?

Some manufacturers specialize in large-scale production for established brands, while others excel at supporting startups and small businesses. Make sure their typical client profile aligns with where you are in your business journey.

Can you provide client references or case studies?

Any reputable manufacturer should be willing to connect you with current clients or share success stories. This gives you deeper insight into their reliability, quality, and customer service.

What makes your manufacturing process different?

Listen for specific answers about quality control, ingredient sourcing, or proprietary processes. Vague responses about “doing things right” are red flags.

These foundational questions set the tone for your entire conversation and help you quickly spot the best herbal supplement manufacturers worth exploring further.

How to Verify Quality Standards Before Ordering

Quality determines everything. It’s what builds your brand reputation or destroys it. When evaluating best herbal supplement manufacturers, you need concrete proof of their quality commitment.

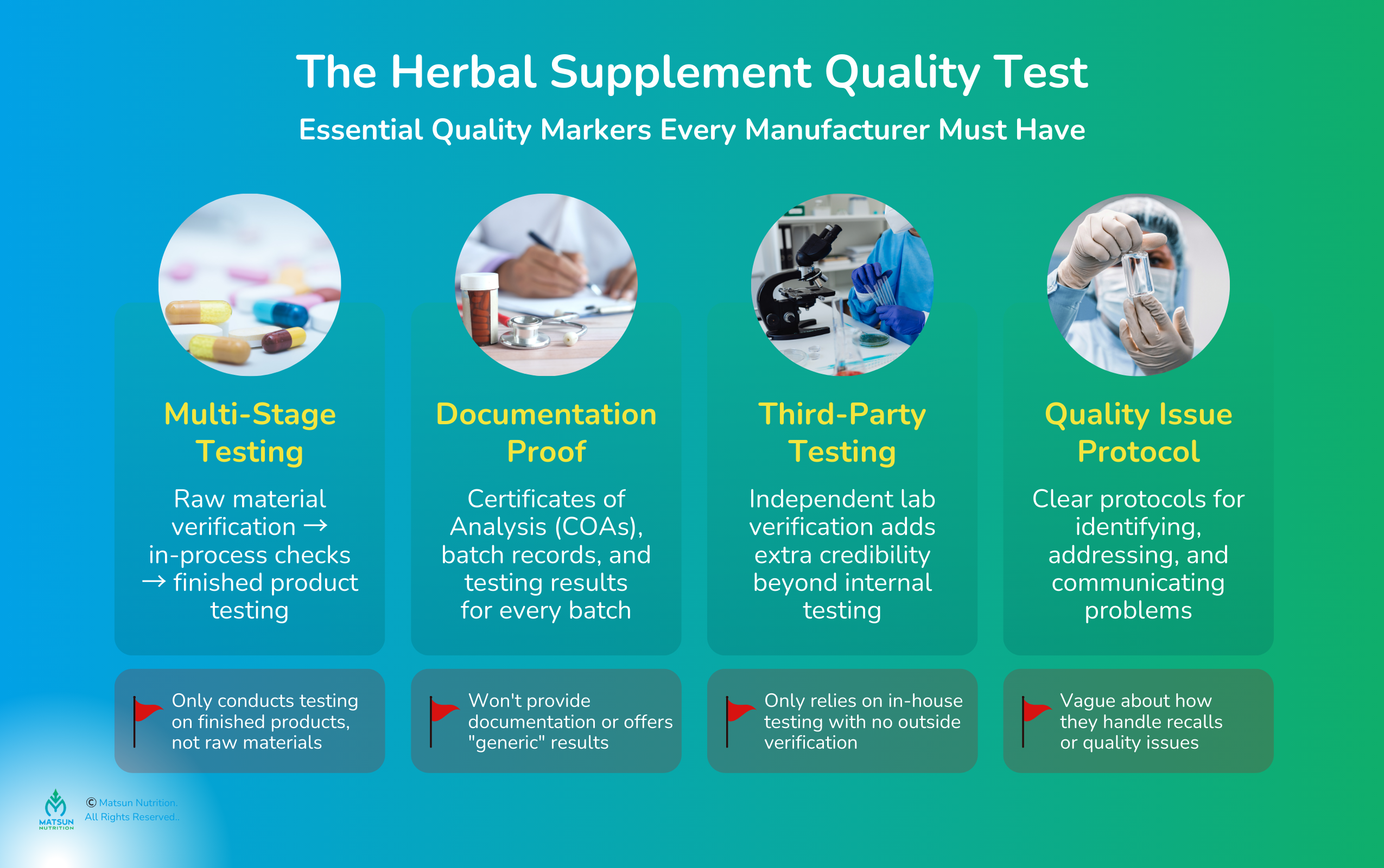

What quality control measures do you have in place? Look for multi-stage testing processes that include raw material verification, in-process checks, and finished product testing. The more specific they are, the better.

How do you handle quality issues or recalls? Their answer reveals their accountability and transparency. A good manufacturer will have clear protocols for identifying, addressing, and communicating quality concerns.

What documentation do you provide with each batch? You should receive Certificates of Analysis (COAs), batch records, and testing results. Without this documentation, you can’t prove compliance or show customers what’s really in your products.

Do you conduct third-party testing? While internal testing is standard, third-party verification adds an extra layer of credibility. Ask which labs they work with and what they test for.

Quality standards directly impact customer trust. If a manufacturer can’t clearly articulate their quality processes, keep looking.

What to Ask About Ingredient Sourcing and Safety

Your supplements are only as good as the ingredients that go into them. When working with private label herbal supplement manufacturers, ingredient sourcing deserves serious attention.

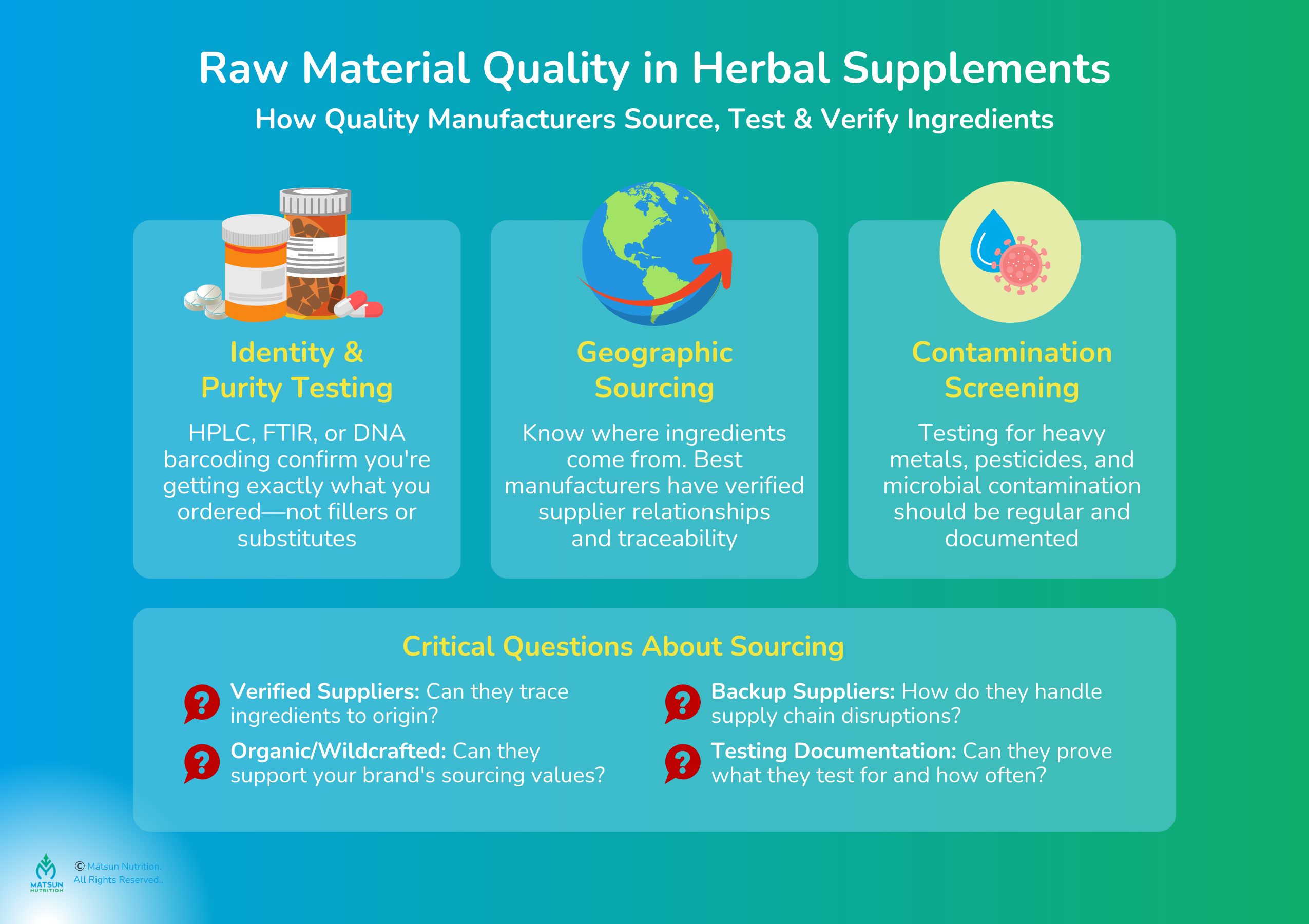

Where do you source your raw materials? The best manufacturers have established relationships with verified suppliers and can trace ingredients back to their origin. Geographic sourcing matters for both quality and supply chain stability.

How do you verify ingredient identity and purity? Ask about testing methods like HPLC, FTIR, or DNA barcoding. These techniques confirm you’re getting exactly what you ordered, not fillers or substitutes.

What steps do you take to ensure ingredients are contaminant-free? Heavy metals, pesticides, and microbial contamination are real concerns in herbal supplements. Your manufacturer should test for these regularly.

Can you accommodate organic, wildcrafted, or sustainably sourced ingredients? If your brand emphasizes ethical sourcing, make sure your manufacturer can deliver ingredients that match your values.

How do you handle supply chain disruptions? Global events can impact ingredient availability. A reliable manufacturer has backup suppliers and communication protocols to keep you informed.

Ingredient quality determines product efficacy and safety. Don’t settle for manufacturers who can’t provide detailed sourcing information.

Herbal Supplement Manufacturing: Industry Best Practices

When vetting a partner, you aren’t just looking for someone who can follow a recipe; you need a manufacturer that adheres to the highest industry standards for safety, efficacy, and transparency. A reputable herbal supplement manufacturer should demonstrate the following best practices:

Strict Identity Testing: Best-in-class facilities use advanced methods like HPLC, FTIR, or DNA barcoding to confirm the botanical identity of every raw herb, ensuring zero cross-contamination or filler use.

Low-Heat Processing: High heat can destroy sensitive botanical compounds. Quality manufacturers utilize cold-processing or specialized low-temperature extraction to preserve the herb’s natural potency.

Full Batch Traceability: From the farm to the final bottle, every ingredient should be traceable via a unique batch number. This level of transparency is essential for FDA compliance and recall readiness.

Microbiological and Heavy Metal Screening: Because herbs are grown in soil, they are naturally prone to heavy metals and microbes. Best practices include rigorous testing for lead, mercury, arsenic, and molds on every single batch.

Stability Validation: Reputable manufacturers don’t guess at shelf life. They conduct real-time or accelerated stability testing to ensure the herbal active ingredients remain effective until the expiration date.

cGMP-Certified Environment: At a minimum, the facility must be cGMP-certified (current Good Manufacturing Practices), signifying that every step of the production process is documented, sanitized, and audited.

RELATED READ:

Key Questions About GMP and Certification Proof for a Herbal Supplement Manufacturer USA

Good Manufacturing Practices (GMP) certification is mandatory for dietary supplement manufacturers in the United States. But not all certifications are the same.

How are your suppliers complying with FSMA requirements, and do you require their Food Safety Plans (FSP) to verify the quality of raw materials?

Why this matters: The FDA’s Food Safety Modernization Act (FSMA) requires raw material suppliers to have a detailed Food Safety Plan (FSP). While the finished supplement manufacturer operates under 21 CFR Part 111, the best partners use the supplier’s FSP as the ultimate evidence that hazards (like contaminants or heavy metals) are being controlled at the source, providing an extra layer of confidence that goes beyond a standard Certificate of Analysis.

Are you registered with the FDA and compliant with 21 CFR Part 111? This is the baseline requirement for any custom herbal supplement manufacturer USA-based. Ask to see their registration documentation.

Can you provide proof of your GMP certification? Request copies of certificates and note the certifying body. Third-party GMP audits from organizations like NSF or UL add credibility.

When was your last GMP audit, and what were the findings? Recent audits with no major findings indicate active compliance. If they hesitate to share audit results, consider it a warning sign.

What other certifications do you hold? Depending on your product goals, certifications like USDA Organic, Non-GMO Project Verified, Kosher, or Halal might matter. Ask which certifications they can support.

How do you stay current with regulatory changes? The supplement industry faces evolving regulations. Your manufacturer should have processes for monitoring and implementing regulatory updates.

Working with manufacturers who take compliance seriously protects you from legal issues, fines, and brand damage.

Understanding Lead Times and Production Capacity

Even the highest-quality manufacturer isn’t valuable if they can’t deliver your products when you need them. Production logistics matter as much as product quality.

What are your typical lead times from order to delivery? Get specific timelines for each production phase: formulation development, raw material procurement, manufacturing, testing, and packaging.

How far in advance do I need to place orders? Understanding ordering windows helps you plan inventory and avoid stockouts that cost you sales.

What’s your production capacity, and do you have room for growth? If your brand takes off, you need a manufacturer who can scale with you. Ask about their capacity limits and expansion capabilities.

How do you handle rush orders or seasonal demand spikes? Flexibility matters. Some manufacturers can accommodate faster timelines for an additional fee, while others have rigid schedules.

What happens if there are production delays? A transparent manufacturer will explain their communication protocols and how they handle unexpected setbacks.

Production reliability directly impacts your cash flow and customer satisfaction. Choose manufacturers who respect deadlines and communicate proactively.

Questions on Custom Formulation and R&D Support

If you’re developing unique products, you need a custom herbal supplement manufacturer with strong formulation expertise.

Do you offer formulation development services? Some manufacturers only produce from existing formulas, while others have R&D teams that can help you create custom blends.

What’s your process for developing new formulas? Look for structured approaches that include feasibility analysis, stability testing, and sensory evaluation.

Can you help optimize my existing formula? Maybe you have a formula that needs refinement for better stability, taste, or cost efficiency. A good manufacturer brings improvement suggestions.

Who owns the intellectual property for custom formulas? This is critical. Make sure you retain ownership of any proprietary formulations you develop together.

What’s included in your formulation fees? Understand all costs upfront, including pilot batches, stability testing, and formula adjustments.

How do you handle formula confidentiality? Your unique formulas are valuable assets. Ensure the manufacturer has strong confidentiality agreements and won’t produce your formula for competitors.

Strong R&D support can differentiate your products in a crowded market. Partner with custom supplement manufacturers who invest in innovation.

How to Confirm Testing, Stability, and Potency

Testing separates guesswork from guarantees. When evaluating herbal supplements contract manufacturing partners, their testing protocols reveal their commitment to quality.

What testing do you conduct on raw materials? At minimum, expect identity testing, purity analysis, and potency verification for all active ingredients.

How do you test finished products? Finished product testing should include potency, microbial contamination, heavy metals, and label claim verification.

Do you conduct stability testing? Stability studies determine shelf life and optimal storage conditions. Ask about their stability protocols and how they establish expiration dates.

How do you ensure consistent potency across batches? Batch-to-batch consistency matters for customer trust. Their answer should include specific quality control checkpoints.

Can I review test results before products ship? Transparency builds confidence. You should have access to all testing data before accepting delivery.

What happens if a batch fails testing? Understand their protocols for failed batches, including investigation procedures and how they prevent recurrence.

Comprehensive testing protects your brand reputation and ensures customers get what your label promises.

What to Ask About MOQ, Scaling, and Flexibility

Minimum order quantities (MOQs) and production flexibility can make or break partnerships, especially for growing brands.

What are your minimum order quantities? MOQs vary widely between manufacturers. Make sure their minimums align with your budget and sales projections.

Do MOQs differ by product type or complexity? Some manufacturers have lower MOQs for simple formulas and higher requirements for complex products.

Can you accommodate smaller test runs before full production? Pilot batches let you verify quality and market demand before committing to larger orders.

How flexible are you with batch sizes? As your brand grows, you’ll need to scale up. Confirm they can handle both your current needs and future growth.

What happens if I need to adjust my order mid-production? Sometimes market conditions change. Understand their policies on order modifications and cancellations.

Do you offer warehousing or just-in-time production? Some manufacturers provide storage solutions that help manage cash flow and inventory.

The right balance of MOQs and flexibility supports healthy business growth without straining your resources.

Questions on Pricing Structure and Transparency

Pricing complexity can hide unexpected costs that erode your margins. When comparing contract manufacture herbal supplements options, transparency is everything.

How is pricing structured? Understand whether you’re charged per unit, per batch, or through a hybrid model. Get clarity on what’s included in base pricing.

What additional fees should I expect? Ask about setup fees, formulation development costs, testing charges, packaging fees, storage costs, and rush order premiums.

How do price breaks work as I scale? Most manufacturers offer better per-unit pricing at higher volumes. Get specific volume tiers in writing.

What payment terms do you offer? Know the deposit requirements, milestone payments, and final payment terms before production begins.

Are there any hidden costs I should know about? Direct questions about hidden fees often reveal surprise charges for things like artwork updates, regulatory documentation, or shipping.

How do you handle price increases? Ingredient costs fluctuate. Understand how and when price adjustments happen, and whether you’ll receive advance notice.

Pricing transparency prevents budget surprises and helps you accurately calculate profit margins.

How to Evaluate Communication and Support Quality

Technical capabilities matter, but communication quality determines day-to-day partnership satisfaction.

Who will be my primary point of contact? Knowing whether you’ll work with an account manager, production coordinator, or rotating staff sets expectations.

How quickly do you typically respond to questions? Response time matters when you’re troubleshooting issues or need quick answers for customers.

What communication channels do you use? Some manufacturers prefer email, others use project management platforms. Make sure their communication style matches your preferences.

How do you keep clients updated on production progress? Proactive updates about order status, potential delays, or production milestones demonstrate professionalism.

Can I visit your facility? Facility tours provide invaluable insight into operations, cleanliness, and organization. Reluctance to allow visits raises red flags.

How do you handle complaints or concerns? Their approach to problem resolution reveals their customer service values and accountability.

Strong communication builds trust and makes the entire manufacturing process smoother and less stressful.

Ready to work with a herbal supplement manufacturer US-based who answers these questions with confidence and transparency? At Matsun Nutrition, we’re committed to quality, compliance, and partnership. Explore our herbal supplement manufacturing services, get a custom quote for your project, or browse our shop to see the quality we deliver. Let’s build something great together.

Frequently Asked Questions

What questions help vet herbal supplement makers?

Start with experience, certifications, quality control processes, and client references. Ask about their GMP compliance, ingredient sourcing, testing protocols, and production capacity. Request documentation for all claims and look for specific, detailed answers rather than vague assurances.

How do I check a manufacturer’s quality process?

Request detailed information about their multi-stage quality control, including raw material testing, in-process checks, and finished product verification. Ask to see sample Certificates of Analysis, learn about their third-party testing relationships, and understand their protocols for handling quality issues.

What sourcing questions should brands always ask?

Find out where raw materials originate, how ingredient identity and purity are verified, and what testing confirms absence of contaminants. Ask about their supplier relationships, backup sourcing plans, and whether they can accommodate organic or sustainably sourced ingredients.

How do I verify GMP certification is legitimate?

Request copies of their FDA registration and GMP certificates, noting the certifying body. Ask about their most recent audit date and findings. Verify registrations through the FDA website when possible, and look for third-party certifications from reputable organizations like NSF or UL.

What should I ask about production lead times?

Get specific timelines for each production phase and understand how far in advance you need to order. Ask about their capacity for growth, how they handle rush orders, and their communication protocols for potential delays. Clarify what factors might extend standard lead times.

How do I compare formulas across manufacturers?

Request detailed ingredient lists, potency levels, and delivery forms. Ask about bioavailability, stability data, and any proprietary processing methods. Compare testing protocols, quality of raw materials, and whether manufacturers offer formulation optimization support.

What pricing questions reveal hidden production fees?

Ask for complete pricing breakdowns including all potential fees: setup, formulation development, testing, packaging, storage, and rush charges. Clarify payment terms, volume discounts, and how price adjustments are handled. Request sample quotes that include all anticipated costs.

How do I assess a manufacturer’s communication?

Evaluate their responsiveness during the vetting process, the detail and clarity of their answers, and their willingness to provide documentation. Ask about their communication protocols, primary contact systems, and how they handle updates and concerns. Consider asking for a facility tour to see operations firsthand.