In a world where custom supplement formulation is integral to creating unique and competitive products, adhering to regulatory requirements is non-negotiable. This approach ensures quality standards are met and safeguards customers from potential risks.

According to a report, the personalized nutrition and supplements market was valued at $10.59 billion in 2022 and is projected to grow at a 16.55% compound annual growth rate (CAGR) between 2023 and 2030.

Starting a custom formula supplement brand can be both daunting and thrilling. To succeed, it’s essential to understand the key requirements and avoid common mistakes in the process. In this guide, we’ll explore 12 costly mistakes to avoid when navigating the world of custom supplement formulation.

Importance Of Custom Supplement Formulation

Most market custom formulas have unique ingredients that can be labeled and custom-made. These are the benefits of custom supplements:

- Help you avoid the competition: One of the most significant benefits of supplement formulation is that it stands out from other companies selling similar supplements. A supplement manufacturing partner should create a formula that is unique to you.

- Address customers’ needs: Custom supplements are beneficial for tailoring your supplements to match your customers’ needs. You will be in a position to serve one of the under-served demographics in need and offer satisfactory solutions.

- Stay innovative: Custom supplements will help you create a new ingredient and know new flavors that might work. It is the best way to set yourself apart from the competition.

- Understand what you need: There’s no better way to know what you want than having one customized supplement. That means you will get a supplement based on the formula, flavor, and color. There is a need to compromise since you will always get what you need.

Mistakes To Avoid In Custom Supplement Formulation

Avoiding mistakes in custom supplement formulation is essential for creating safe, effective, and marketable products. From sourcing high-quality materials to adhering to strict regulations and maintaining proper branding, each step plays a vital role in ensuring success. This guide highlights 12 common pitfalls to watch out for, helping you streamline your process and build trust with your consumers.

Selecting Poor-Quality Materials

In the same way, high ingredients make nutritious and delicious food; the same is true for the raw materials for supplement formulation. Non-compliance elements often put the consumers’ health at risk and fail to provide the added benefits they seek when adding their daily supplement dose.

Therefore, selecting custom supplement formulation services from a reputable team reduces health risks, which will also cause severe issues for your intended clients and the firm.

Using Ingredients Incorrectly

There is a rise in self-taught artisan formulators on different social media platforms, which sometimes don’t always go hand in hand with the actual formulation.

Hence, you should take precautions before engaging such individuals and never rely on information lacking professional backing. Don’t simply assume that a botanical ingredient that’s said to have a particular chemical compound will automatically become an excellent formulation for your supplement.

Instead, know some of the elemental composition. For instance, some online sources vouch for Rose Absolute for its soothing and anti-scarring benefits to the skin, with many recommending using high amounts of over 1% in your formulation. However, according to IFRA standards, rose absolute has methyl eugenol, a regulated carcinogen.

Ignoring The Regulations

The Food and Drug Administration (FDA) isn’t mandated to approve supplements circulating in the market. However, it has established Good Manufacturing Practices (GMPs). These are the rules that different manufacturers must follow to identify dietary supplements’ composition, strength, and purity. Therefore, failure to comply with these standards will result in costly fines and product recalls.

Dirty Facility

Never work with a nutrition manufacturer who doesn’t maintain clean facilities; poor hygiene will introduce harmful bacteria into the dietary supplements during formulation. That puts your customers at risk. Ensure that the private label products are manufactured in some of the cleanest facilities ever.

Lack Of Proper Testing

Failure to test your products might be one of the greatest mistakes anyone would ever make. Skipping testing means you cannot guarantee your consumers that the supplements have the right ingredients and amounts.

Testing isn’t only mandatory but also crucial in ensuring the efficacy and safety of all your formulations while at the same time keeping the end user safe. So, find the proper supplement contract manufacturer that doesn’t compromise in this phase.

Not Knowing The Turnaround Times

Working with a company that offers transparency on how long the process will take is essential. Each custom supplement manufacturer has their time limit, so find one that best suits your needs. Avoid those giving you a quick turnaround time, like four weeks. While this is technically possible, it is best to avoid this so you don’t end up with a low-quality dietary supplement in circulation.

Failure To Conduct Market Research

You should know your demographics before creating the product. The critical formula to success for your dietary supplement is through market research. Know your audience well to understand which formula will appeal to them.

Liquid multivitamins are quite popular because they are easy to absorb and digest. Hence, understand some of the changes the customers might want before choosing a private-label liquid multivitamins before investing in the process.

Complicating The Formulation

You want to create something that your customers will love and enjoy. So, you should know how many of every ingredient must be included.

Research and determine what elements are necessary since they lay a foundation for your product. Keep the formulation simple. Find a reliable white label supplement manufacturer with personalized solutions that fit your needs.

Formulating Without Intentions

If you don’t know what your supplement will be helpful for, then investing in this process is wrong. Have a clear understanding of the end goals and how beneficial the dietary supplement will be to the consumers. That helps determine the necessary ingredients and qualities you should use before the supplements are formulated. For instance, an immune support shot with vitamin C and zinc would help boost immunity and reduce inflammation.

Lack Of Proper Branding

Proper branding ensures you get the message across quickly without confusing your audience. Find a company that will assist in creating a cohesive brand to maintain the right tone, which is attractive to potential customers. The design should be suitable to set you apart from other suppliers online or in different physical stores.

Marketing Over Science

You should never fall for the hype. Just because a specific formulation ingredient is trending doesn’t make it safe or suitable for your custom formation. Prioritize ingredients that have a valid scientific balance and are safe to deliver actual results to your consumers.

Having Unrealistic Cost Expectations

Most people assume that because the supplement is costly, more customers will buy it. However, remember that a high-quality supplement will be pricey to supply. Therefore, get a team that will assist in balancing your vision and real-world expectations. It becomes effective and profitable, thus creating a solid foundation for you to supply your products.

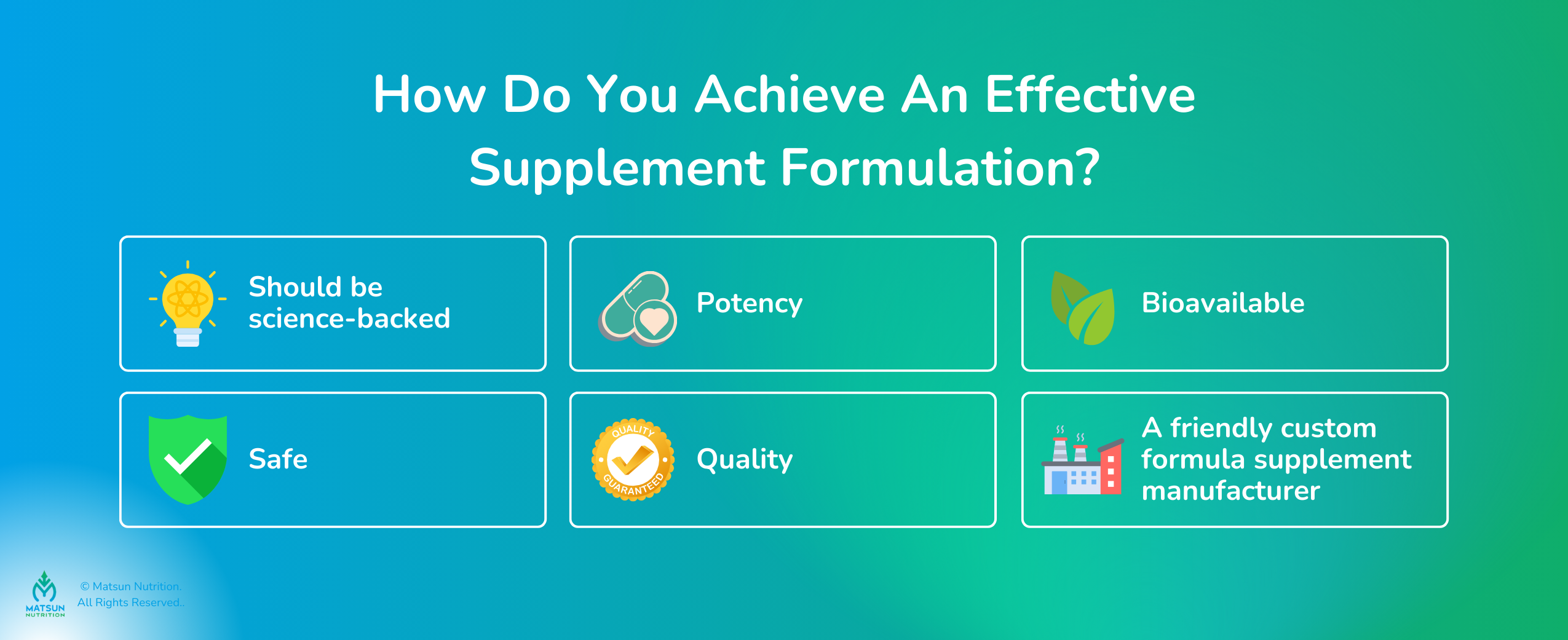

How Do You Achieve An Effective Supplement Formulation?

The ideal way to have an effective formulation is to have suitable ingredients and blend in with high-quality ingredients in accurate amounts. Here’s what you should know about the formulation recipe:

- Should be science-backed: Ensure that credited scientists effectively research your ingredients and dosages.

- Safe: These ingredients should meet the FDA regulations for human consumption.

- Potency: The goal is to have a dietary supplement full of potency throughout its shelf-life; therefore, ensure the company you work with guides you through the process.

- Quality: Pick cost-effective but high-quality ingredients that can assist you in pricing the product well while still making the proper profit.

- Bioavailable: Dietary supplements must be readily absorbed in the body since that’s the only way they will work effectively and provide maximum consumer benefits.

- A friendly custom formula supplement manufacturer: Work with a company that allows a smooth production process so your business can sail without complications or delays.

Requirements For Custom Supplement Formulation

If you want your business to succeed, work with legitimate and licensed wholesale protein powder manufacturers and one who can make other supplements. They will ensure you don’t incur the errors discussed above. That includes having the correct branding, conducting target audience research, and testing every batch after formulation.

Matsun Nutrition has decades of expertise in innovative dietary supplement formulation, thus boosting customer satisfaction. There’s always a chance to navigate through some of the most complicated aspects of manufacturing supplements, avoiding unnecessary expenses that could result in your company’s downfall.

Also, Explore the diverse range of Matsun Nutrition products, including Liquid Vitamins, Powder Supplements, and Gummy Vitamins – available for private label, custom formulation, and white labeling.

Frequently Asked Questions

It refers to creating dietary supplements that match specific needs and preferences. Therefore, the owner knows the ingredients that best work based on their efficacy and safety.

Most companies ensure that all the raw materials undergo intense lab testing for potency and heavy metal testing. After manufacturing, the products undergo the same procedure to ensure safety before being supplied to the target consumers.

It refers to a specific business model where a firm buys and rebrands a third-party manufacturer’s products. This differs from contract manufacturing, where the company designs and contracts a manufacturer to make it.

Designing a custom supplement formula involves many steps, including identifying the supplement, knowing the ingredients to use, and picking the proper packaging. Developing a unique supplement formula needs more time and effort but is worth the investment, so you should study this extensively and ensure you don’t skip a stage.